The design basis of injection plastic products 2- Parting line of Injection Mould

The design basis of injection plastic products 2- Parting line of Injection Mould

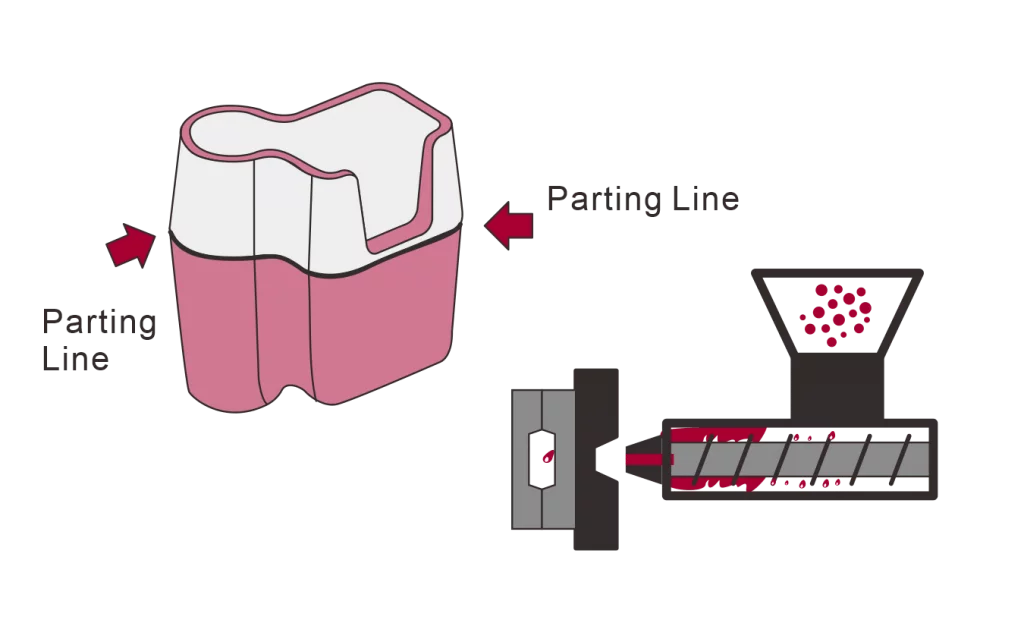

The injection plastic parts must be removed from the mould after the completion of plastic injection moulded products.

If the injection mould cannot be opened, it cannot be removed either. So a set of plastic moulds must be divided into the mould and down mould, or the left and right mould.

However, the injection moulding parts is a crack in the combined mould position because the plastic injection time must be the pressurized plastic filling of the mould, So no matter how close the mould is, with today’s technology, the plastic is more or less bound to be squeezed into the gap. When the mould comes out of the mould, it leaves a mark in the gap, which in the plastic world is called a mark.

Looking at this trace carefully, you will find that the parts have a bit more plastic out of them. The injection parts have too much plastic called “Sometimes the mould is poorly designed, or the mould is worn and neglected so that the two moulds can not wholly fit together, resulting in dislocation, and an obvious step will be formed.

Because the plastic line is due to the joint formed by the mould, so in the mould design will be decided at the beginning of the plastic line, but also because the location of the PL will affect the follow-up mould opening position, so avoid because mould corner (undercut) cannot refund mould problem, such as a plastic cup in hand, parallel to the parting surface is best to handle, In case the hand is still buried in the mould after parting.

The following is lists some considerations when deciding on parting surfaces:

- the parting surface is best designed along with the corners or edges of the moulded parts so that even some small edges are less likely to be detected.

- It is best not to put a parting surface with appearance requirements. If you must appear it on the outside, please set it to a less noticeable area. The minimum texture you should use minimizes the parting line’s appearance.

- If the position of critical dimensional mechanisms is available, try to avoid designing the component die surface, as the dimensions of the die parting surface are more difficult to control.

- When the moulding part has a dead corner, it should be fully considered for the mould part.

- When the parting surface is not easy to deal with, you can use the method of post-processing to polish and remove, but this will increase the cost of injection moulding parts.

Categories

Share On

Recent Post

Injection Molding Defects: Brittle crack

Here is a painful lesson learned by one of our

Everything You Need To Know About Laser Welding

Laser welding is a high-precision method for joining materials that