If you keep it simple, the answer to 3D printing a rubber is ‘No’. You can’t 3D print a pure rubber directly because of its properties. it is an organic product that comes from latex and latex comes from trees. Being an organic product means that it is very hard to influence its properties with external factors like temperatures, radiation, etc. Such materials are not industry acceptable because of their complex properties, so to make them acceptable they are made to undergo a process where the rubber is heated at a high temperature. The process is also called vulcanization as it is burned and hardens the rubber so it can be converted to a fluid state again. After the process, it is converted into a thermosetting polymer from a rubber.

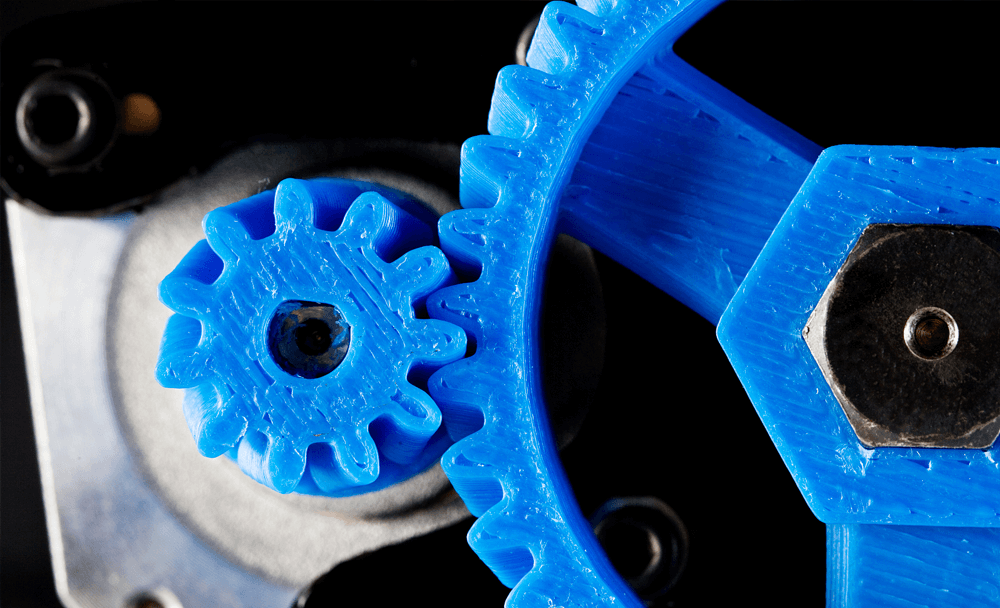

Synthetic materials are a good replacement for rubber and are more suitable for 3D printing because they can be liquified in a very controlled way. One example of it is thermoplastic elastomers. They are suitable for printing because of their rubber-like properties which include good flexibility, durability, bending, and compressing. Materials like these are also used in the 3D printing industry for different applications because it allows the manufacturers to stimulate the properties of the materials according to the requirement of the material whether it is heat or radiation resistance, abrasion, or others.

These rubber-like materials are used in different applications such as shoe soles, sealing of rings, soft gripe handles, or also for industry models that require shock absorption, etc.

Try Made by Aria Now

All information and uploads are secure and confidential.

Also Read: How much does it cost to 3D print a part?

Alternatives Of Rubber 3D Printing

Flexible Filaments For 3D Printing

The demand for printing through flexible filaments is continuously increasing in the market and the 3D designers continue to research, discover new techniques and find out new ways to deal with the filaments so that the result of rubber 3D printing can be improved and the materials printed can get the same feel or friction as the rubber material.

There are several flexible filaments in the market but some of the most commonly used ones are Thermoplastic polyethylene, Thermoplastic elastomers, and Thermoplastic copolyester. There are many benefits of these materials, on top of flexibility including elasticity, strength, durability, flame resistance, and shock retardancy. They give long-term skin contact, as they are used in the materials like electronic watches, etc. Due to their antibacterial properties, they are also considered good filaments for food safety.

The same results of the flexible filaments are as rubber can be achieved but for the filaments, there are some conditions because it is already very difficult to print flexible materials in a 3D printer. There are certain factors that need to be taken care of when printing them. One of them is to always print at a very slow speed when you are printing using rubber-like filaments which have elasticity. These materials don’t perform well at high speed and the results are mostly ruined because of it. They take more time than other filaments so it is recommended to always print with these filaments at a speed of 20-40mm per second.

The second factor that affects the 3D printing of rubber-like filaments is temperature. Stopping at the correct temperature is very important and for that, you should start with the temperature that is recommended and then go around it. The temperature affects the print quality so adjust the temperature until the desired print quality is achieved.

Flexible Resin For 3D Printing

Another alternative to rubber is flexible resins as they allow manufacturers to print flexible and the parts with high elasticity. The printers for resin are different and printing resins requires a lot of precautions. During the resin printing, these printers release organic compounds like VOCs which are harmful to the respiratory system. Because of that reason, it is recommended to use a secondary enclosure or air filter. It is to make sure that in the room where the printing is being done, there should be good ventilation. It is to make sure that the work surfaces should always be covered by the towels that are damped in water so that any case of splash or mishappening can be avoided.

Different parts of a 3D model printing through resin can be printed with a design that has a certain angle in them so that it stays in the shape otherwise the flexibility will make the part flat again. The different properties of a resin can be distorted like the flexibility of resin material can be reduced. If a certain part is printed at an angle, then it will reduce the elasticity of that area. You can also try different experiments with such models that have 50% of resin and 50% other filaments so that the product can be rigidly altered.

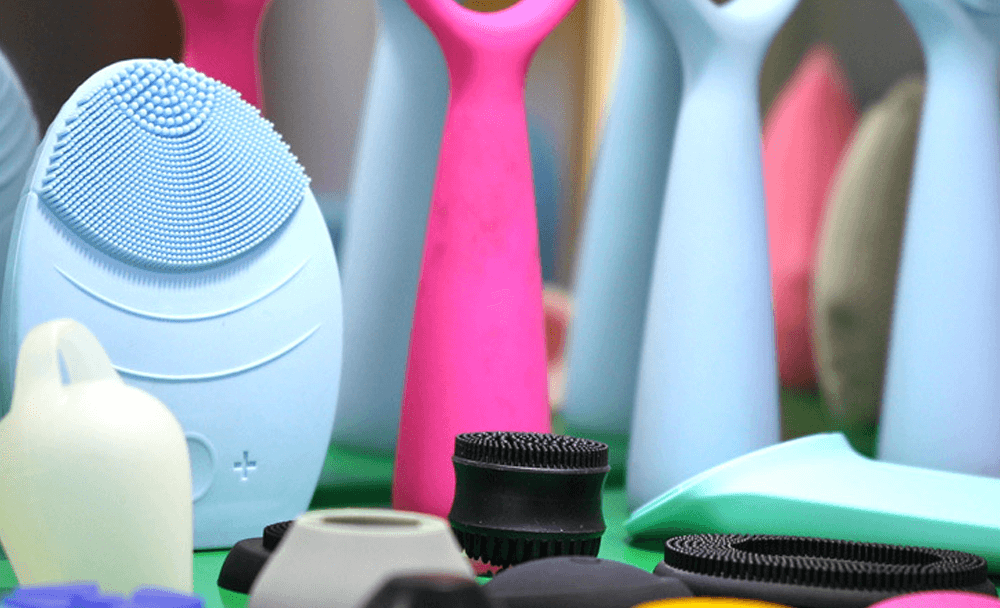

Silicone Printing for 3D Printing

3D printing with silicone is a difficult task and some technologies are still in their early stages of development but hold very promising results in some fields. It is basically a silicone in a liquid form initially that is later converted into solid rubber form by different processes like vulcanization, catalyzation, or curing. Full strength is required after these processes on solidifying the silicone process by curing.

There are only some specific printers that can print silicone materials. There are a lot of companies that are developing printers that have the technology to print silicone with the great printing quality. Printers like FDM and SLA are not capable of printing silicone rubber due to their properties. Silicon rubber has some very useful characteristics like thermal stability, biocompatibility, and UV resistance. There are a few 3D printing suppliers that are providing 3D printing services for silicon.

What Is Injection Molding?

Just like 3D printing, Injection modeling also allows the printing of materials like TPU. Both of them require heating the rigid thermoplastics at high temperatures to liquidity them and then cooling them down to solidify them while still having rubber-like properties such as flexibility and other characteristics. Injection molding for rubber is becoming a popular process nowadays because of its simplicity and its use in different fields. Rubber injection molding distributes uncured supplies through a mold using a nozzle and strategically located sprues and sprinters. Injection molding mostly has its root in plastics and manufacturers can experiment with different designs and materials. There are mainly three types of injection molding as listed below

- Organic Rubber Injection

- Thermoplastic Rubber Injection

- Liquid Injection Molding (LSR Injection)

A wide range of designs is offered by the silicone injection molding than the plastic one because silicone parts are more flexible and can be easily removed from the molds they solidify in without the use of draft angles. 3D printing and injection molding both have their own pros and cons when it comes to printing flexible materials like rubber, etc.

Try Made by Aria Now

All information and uploads are secure and confidential.

Pros and Cons Of 3D Printing Rubber

Advantages of 3D Printing Rubber

- Low Cost

Printing 3D printing an object is cheaper than injection molding because injection molding requires mold for printing which is highly expensive, and approximately around $100,000 each. The cost of traditional 3D printing a rubber is much lower and is almost equal to 3D printing a silicone. Since it requires no molds to print parts of an object, so it highly reduces the cost of the overall process and the manufactures can also change the designs of the object every time since there is no mold that has to be used each time.

- Reliable Products

Rubber products that are printed from a 3D printer are very durable and reliable. Since they are flexing enough to avoid the damage that can be caused to a model. The original structure of the product can be retained even if it is tried to squash, bent, or anything like that because of its impact-resistant nature so it lasts longer compared to the other products.

- Less Chance Of Distortion

The reasons why it is recommended to 3D print rubber-like materials at a low temperature are to avoid any damage to the object or weakening its properties of it like flexibility, elasticity, etc. Another reason for that is to avoid any distortion of any part of the object because it overall makes the final results reliable, and durable due to which they require less care after being printed.

Disadvantages of 3D Printing Rubber

- Damage to 3D Printer

Printing at a very low temperature is recommended by professionals so that the printing quality of the object is not compromised. But it is also a con to it, having a low temperature to print can increase the risk that the filament will get hard or get solidified resulting in clogging by blocking the nozzle itself. This damages the 3D printer itself because it gets very hard then to unclog the nozzle and that will affect the printing.

- Prone to Stringing

Due to the low temperature, the filament gets prone to stringing as the leftover strands of filaments will stay on the print bed. A dirty print head can ruin the quality of the print because the print bed is a very important part of a printer and the final results of the print are on it.

- Difficult Post Processing

The rubber-type materials once solidified can not be converted into a liquid again. So the post-processing of such models is very difficult. Once the parts are complete, it is impossible to remold them or alter their shape by any method. So, with such printings, the manufacturers have to be very precise and careful, because once it is ruined, the filament, money, time, and efforts all get wasted and can not be regained.

- Poor Bed Adhesion

One of the biggest problems with the rubber filaments is that they start sticking to the bed which means poor bed adhesion. If the filament starts sticking to the bed that means that it gets very difficult for a proper base layer of a 3D print on which the whole 3D print has to be built. Although, this problem has a solution which is to change the bed material of the 3D printer. Using adhesives on the print bed such as glue or tape can also solve the problem but due to that, the print quality can be compromised by increasing the risk of deformed parts, resulting in cracks and splits making the print useless.

Applications of Rubber 3D Printing

There are several applications of rubber 3D printings including that in medical, sports, orthopedics, transport, and many more.

The sporting goods market is moving towards making many of its products by 3D printing them. In indoor gymnastics and martial arts, shockproof goods are used that are printed by rubber 3D printing. One of the biggest are of sports where it is used is the grips for different tennis and badminton rackets. The bike grips are also made from 3D printed rubber materials so that it is easy to hold and get a grip. Many big companies like Adidas and Nike are also moving towards 3D printing of their shoe sole and other parts of shoes and they are also better than the traditional ones.

Orthopedic is also a field where 3D printing is playing a vital role to help make the products to reduce leg and back pain. Rubber is very soft and is being used in the cushioning of the products like the sole of the shoes. Doctors design and 3D print products according to the needs of the patient individually.

Another industry where rubber 3D printing is used is transport. The tires and grips of different vehicles are printed through them. Although, they are incapable of printing large tires so the industry is still working to scale their machines and printers up so that the production capacity is increased. Many popular bike and car companies are incorporating 3D-printed parts in their new vehicles that are being produced. The rubber 3D printing of these materials has reduced a lot of costs by cutting a lot of waste during production.

So, it is all clear from the above discussion that 3D printing a rubber is not possible yet but three are different alternatives present for that. These rubber-like materials give you the exact feel of rubber having the properties like elasticity, durability, flexibility, and much more. However, if you want to print some rubber objects and want to achieve the same results there are a lot of alternatives but do take care about the print settings to retain the print quality.

Try Made by Aria Now

All information and uploads are secure and confidential.

Categories

Share On

Recent Post

CNC Machining Guide Explained

Computer Numerical Control (CNC machining) is a cornerstone of modern

Automotive CNC Machining Explained

From the first hand-made engines to the current computer-operated factories,

Fillet vs Chamfer: How They Difference and Their Uses

When designing parts that stack together, edge is a predominant

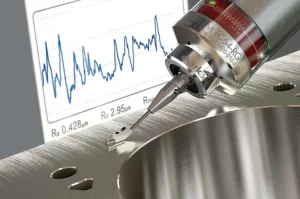

What is Surface Roughness: Symbols Chart & Measurement Method

Surface roughness plays a critical role in mechanical engineering, machining,

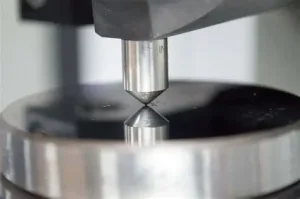

Understanding Material Hardness: Types, Testing, and Applications

Material hardness is one of the fundamental properties of a

CNC Machining Guide Explained

Computer Numerical Control (CNC machining) is a cornerstone of modern

Automotive CNC Machining Explained

From the first hand-made engines to the current computer-operated factories,