In the design and development of injection mold, the factors that need to be considered are product appearance, product size, injection mold demoulding, mold structure, etc., because they will affect the design of parting surface; this paper mainly discusses the impact of injection product appearance and product size on parting surface design.

Injection molding products have appearance requirements

When injection molding parts need to be assembled, the outer surface of the product or part of the area is not allowed to have a parting line; if parting, there will be a parting line, flying edge, fault, and other problems. However, the parting surface on the product feature line will not affect the outer surface of the injection product.

Injection molding product surface has distance size requirements, profile requirements, flatness requirements

If we design the surface with size requirements on the fixed die side, the forming part of the moving die side and the parting surface are in the same plane; when the product is not qualified due to deformation or warping and other reasons, iron will not be added on the moving die side, resulting in a scrap of the die. If the parting surface is raised 0.2-0.5mm, when the size of the product is not qualified due to deformation or warping and other reasons, it is very easy to add or reduce iron on the moving die side.

Injection molding products have coaxial requirements

For injection molding products with coaxial requirements, we should try to put the characteristics of coaxial requirements separately on the same side of the mold moving mold or fixed mold, To reduce the product coaxially out-of-tolerance problem caused by assembly and mold closing error. The parting can not be placed on the same side of the mold; it can be done on the parting surface of the product circumference to reduce the influence of mold closing error on the coaxially of the product.

Injection molding products have trimming requirements

When the parting surface of the product has trimming requirements on the cutting edge, the parting surface is designed. The cutting edge of the parting surface will face outward along the parting surface. In addition, the fault difference caused by the mold closing accuracy will also enlarge the cutting edge size, leading to unqualified products. The correct design guide of injection mould will be referring to the product shape or functional requirements and, combined with the precision of the mold to move 0.03-0.05mm to one side, will reduce the burr and hole mold on the cutting problem.

Categories

Share On

Recent Post

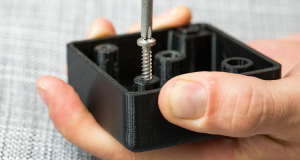

Self-tapping Screws Of Plastic Injection Molding Parts

In the development and design stage of new products, the

Injection Molding Screw Post Design Guide

The screw is one of the most commonly used locking