CNC, which stands for Computer Numerical Control, is a method of programming a machine tool to do various kinds of machining. It is a huge industry and is used to do everything from creating plastic prototypes to creating parts for rockets and missiles. CNC is a powerful and versatile technology and can be applied to a wide variety of materials and parts. If you want to get started in CNC machining services, read on to learn more.

1. What is CNC machining?

CNC machining is a manufacturing process in which materials are removed using computer-controlled tools. The process starts with a CAD file or a three-dimensional model of the part that needs to be machined. This file is used to create a toolpath, which is a series of instructions that tells the CNC machine how to cut the part. The CNC machine then follows these instructions to remove the desired amount of material from the part.

2. Different types of CNC machines

There are three different types of CNC machines: 3-axis, 4-axis, and 5-axis. The main difference between these machines is the number of directions in which the cutting tool can be moved. 3-axis machines can move the tool in three directions (X, Y, and Z), while 4-axis and 5-axis machines can move the tool in four and five directions, respectively. Which type of machine you choose will depend on the specific projects you want to work on.

3. How much money should you invest in a CNC machine?

The next question on your mind is likely to be, “How much money should I invest in a CNC machine?” The answer to that question depends on the type of CNC machine you’re looking for, the features you need and your budget. Generally, you can expect to spend anywhere from a few thousand dollars to tens of thousands of dollars on a CNC machine. It’s important to do your research and find the machine that’s right for your needs. You don’t want to end up spending too much or too little and regret your decision later.

4. Building or purchasing a CNC Machine

The first step in getting started in CNC machining is to build or purchase a CNC machine. If you are new to CNC machining, it might be best to start with a small machine that is easy to operate and doesn’t require a lot of space. There are many different types of CNC machines on the market, so it is important to do your research and find the one that best meets your needs. You can find CNC machines for sale on various websites, or you can build your own machine using a kit or plans.

5. What Software Should I Use?

Even if you have never worked with computer-aided design (CAD) software before, you can still get started with CNC machining. Inexpensive software like SketchUp is relatively easy to use and can help you create models of parts you want to machine. Other CAD software, like AutoCAD, is more complex but can provide more features and options. It is important to use software that is compatible with the type of CNC machine you are using.

Step-By-Step Guide to Making CNC Parts

Design Idealized Part with CAD

Computer-aided design (CAD) software allows you to design 3D objects to be machined on a computerized numerical control (CNC) machine. The object is created in a virtual space, which you can then manipulate to get the desired results. You don’t need to be a engineer or artist to use CAD software–many programs come with pre-loaded templates and designs that you can use right away, or you can create your own designs from scratch.

Modify Design for Manufacturing Needs of the part with CAD

CAD software is used to modify designs to accommodate the manufacturing process and the part’s specific needs. The software allows the designer to see what the part will look like once it is manufactured and find potential problems with the design before the part is ever made. For CNC machining, the CAD software can be used to create a toolpath that will guide the CNC machine as it manufactures the part. The toolpath will take into account the size and shape of the part, the materials being used, the manufacturing process, and any special requirements the part may have.

CNC Programming

So what is CNC programming? CNC programming is a process that takes a 3D model or drawing and translates it into a set of instructions that a CNC machine can understand. This process is essential in order to create the desired product. In order to become a CNC programmer, you’ll need to have a strong understanding of mathematics and geometry, as well as experience with CAD software. There are a number of different CAD software programs on the market, so it’s important to find one that suits your needs. Once you have a CAD program, you can start creating 3D models of your products. These models can then be programmed into a CNC machine to create the final product.

CNC Machine Setup

Once you have your CNC machine, you need to do some basic setup. This includes calibrating the machine, homing the axes, setting the working zero and configuring the spindle. calibration is the process of adjusting the machine so that the cutting tools are in the correct position. the homing procedure tells the machine where the zero point is so that it can return to that location whenever it needs to. setting the working zero establishes the point from which all other coordinates are measured. configuring the spindle tells the machine how fast to spin and how much torque to apply.

Program Proofing for Parts in CAD

One of the most important steps in CNC machining is program proofing. This is the process of checking the part program to ensure that it will produce the desired results. In CAD, you can use simulation tools to preview the machining process and check for errors. This is an important step to ensure that the part is correct and there are no surprises when the program is run on the machine.

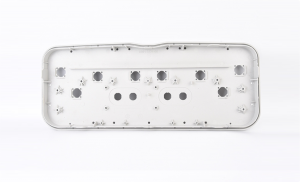

Manufacturer Quality Control and Part Inspection CNC Machining

CNC machining centers have become an important part of the manufacturing process for many products. Standard inspection and quality control procedures are essential, but when using a CNC machine to produce parts, QC and inspection take on a whole new level of importance. The use of a CNC machine introduces a certain level of variability into the manufacturing process, and the part may not meet the customer’s specifications. To avoid rejects and the associated cost, it is essential to have a robust inspection and quality control procedure in place. This should include inspection of the machine setup, the machining process, and the final part.

Finishing Part is Ready – CNC Machining

Congratulations, you’ve completed the machining process! The last step is to finish the part. This is usually done with a grinding wheel, which smooths and shapes the part to the desired finish. Be sure to use the same type of wheel as the one used to create the rough shape, or you may end up with an undesired finish. In most cases, the grinding wheel will be the only step needed to bring the part to the finished state. However, in some cases a light buffing with a polishing wheel may be necessary to achieve the desired results. And there you have it! Your finished part is ready to be used in whatever project you have in mind.

Categories

Share On

Recent Post

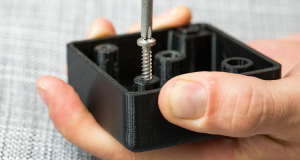

Self-tapping Screws Of Plastic Injection Molding Parts

In the development and design stage of new products, the

Injection Molding Screw Post Design Guide

The screw is one of the most commonly used locking