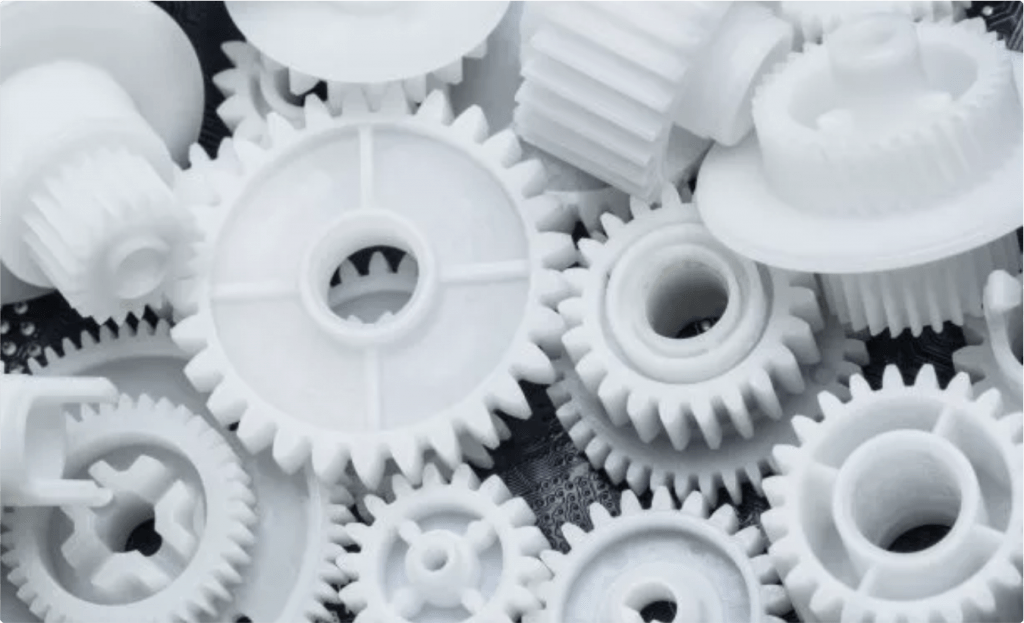

Injection molding technology is one of the most common methods used in the plastics processing industry. It allows you to get ready-made elements of almost any shape.

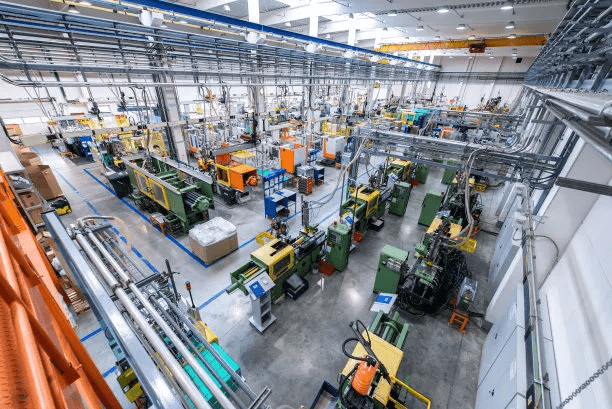

For a material such as plastic, injection molding is a very efficient injection technology. It has been known since the first half of the last century. Since then, the technology has been constantly improved – in response to ever new types of plastics, the needs of subsequent industries seeking this method, and ever-increasing demands from the end users of the products.

Plastic injection molding - what is it?

Thermoplastic injection molding is a standard process that uses a mold. The volume of which is filled with a polymer melt. The injection molding machine allows injection pressure and speed, quality control and minor errors, so products are usually ready to ship immediately after production.

The plastic granulate is loaded into a cylinder where it is melted, compressed and injected into the mold channels. The hot material solidifies in the mold space and thus the cast element is created. Plastic injection technology means that ejectors eventually remove the part from the mold, which falls into the supply tank. As soon as the series is ready, the parts (or the main series) are immediately packed and shipped.

Process features

In order for the injection molding process to proceed smoothly and the resulting product to be of good quality, it is necessary to ensure the appropriate parameters during the implementation of each injection molding cycle.

An important element of the plastic injection molding process is duration. That is, the time that the plastic remains in the mold under high pressure while solidifying. Usually it is from a few seconds to about twenty. Most often, this time depends on the type of material, as well as the size and weight of the product.

Too short a pressure may cause the surface of the product to collapse or cause other damage. Leaving the material for too long is not beneficial. High pressure that is maintained for a very long time can cause the material to be over-sealed and make it difficult to remove the product from the mold cavity.

Plastic injection molding involves the use of special molds

They usually consist of two parts: one is attached to the table of the casting machine, and the other is movable, from which the finished product is removed.

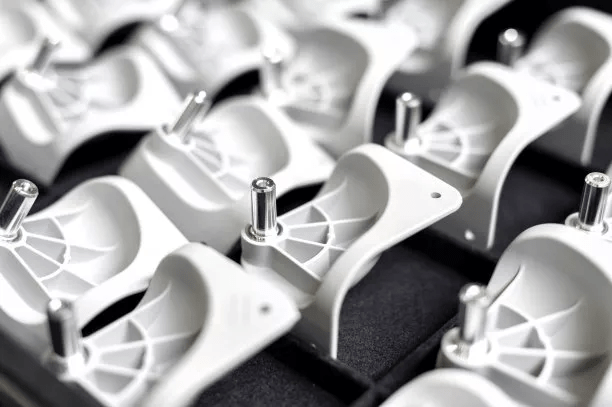

If the forming object is large, then the form will have one nest. However, when small parts are produced, it happens that the mold has several or even about ten forming cavities. This increases the efficiency of the entire process. Depending on the number of seats, the molds can have a different number and different lengths of channels that distribute the plastic mass.

Benefits of injection molding plastic parts

- High precision and aesthetics

Plastic injection molding is a method of manufacturing products, which is characterized by excellent quality, high precision, aesthetics and the ability to repeat the size of the resulting products.

- Speed and Efficiency: Rapid Production of Plastic Parts

The fast and efficient nature of this type of production makes it the most popular way to produce large-sized plastic products (both for everyday use and for highly specialized purposes). However, the actual time to create each element will depend on the complexity of the mold itself. Typical molding time varies from a few seconds to several tens.

- Minimization of labor costs

Try Made by Aria Now

All information and uploads are secure and confidential.

Reduce waste, energy consumption and emissions

The ability to minimize waste and emissions of compounds harmful to the environment and health is an advantage for everyone. The whole process is characterized by high repeatability, which reduces the amount of waste generated. The resulting waste is then recycled so that it can then be used in another production.

- Production flexibility

Plastic injection molding provides more flexibility and the ability to make changes throughout the manufacturing process. For example, change color, use materials with different degrees of strength or additives that affect resistance to external factors (such as UV or chemicals).

Plastic injection molding is ideal for producing custom parts or making functional prototypes. This technology is often used by manufacturers of not only children’s toys and medical equipment, but also components for the automotive or aviation industries of the knowledge that plastic has found in human life.

Everyone should be aware of the fact that from time to time we use objects or devices created from some kind of artificial material. Today it is difficult to imagine a world without plastic. It has become an integral part of everyone’s daily life.

All about plastic: advantages and disadvantages

Although the use of plastics has its disadvantages, in the end, the advantages of such a material are clearly greater. For example, this:

- the ability to easily create even very complex and irregular shapes (a good example is 3D printers or molds for making objects by injection molding);

- light weight;

- high mechanical strength;

- durability of manufactured products;

- good electrical insulating properties;

- high chemical resistance;

- possibility of processing (in case of separation of waste);

- Light toning.

The main disadvantages of plastics are:

- low resistance to high temperatures;

- very long decomposition time (plastic waste decomposes only after many tens or even hundreds of years);

- Susceptibility to creep (that is, a slow change in shape as a result of the action of a given object or material under constant and prolonged loads).

Now you already know the designation of plastic and the properties of different types. Plastics are not as dangerous as they have been thought for many years: of course, provided that they are properly processed. Knowing how long plastic takes to decompose (some types even up to 1000 years!), it is worth remembering that used or broken items made of polymer materials should be thrown into separate waste containers.

This will not only help keep our environment in the best condition, but it will also indirectly affect the prices of plastic products – their production from recycled materials is very cheap.

Try Made by Aria Now

All information and uploads are secure and confidential.

Plastic injection molding: features and benefits

Among the techniques for transforming plastic materials, the most widespread is injection molding.

In this industrial production process, the plastic material is melted (plasticized) and injected at high pressure into a closed mold, which is then opened after the solidification of the product.

What is this technique used for?

It is a rapid technique designed for the production of large quantities of the same plastic product.

For this reason, injection molding is useful in the production of plastic parts and spare parts: from medical equipment to toys, from bottle caps to remote control shells or it is also used to create products for the aerospace and automotive industries.

The injection molding manufacturing process involves melting plastic in the molding machine (called an injection molding machine) and then injected under high pressure into a mold.

The material here cools, solidifies and is then released through the opening of two valves of the mold.

The advantages of this type of processing are:

- high productivity

- low production costs, given the high automation of the processes

- possibility of producing parts with complex geometries, very small, but also very large

- Production of artifacts with different colors and materials.

What are the plastic materials used in injection molding?

For injection molding, thermoplastic polymers are used which can be repeatedly melted or softened by heating and solidified by cooling. It is important to distinguish which type of thermoplastic material should be used based on the type of product to be made.

Materials such as polyethylene, polycarbonate, nylon, polypropylene and high impact polystyrene are widely used in this type of production. Choosing the right material for your application can result in increased performance and reduced costs.

Conclusion

Plastic injection molding may seem, to those unfamiliar with the industry, like an extremely complex process used to make sophisticated products, but it is not.

In fact, many ordinary products, including many disposable components, are made with this industrial technique, such as plastic tableware.

Therefore, the applications are innumerable and the potential products that can be made are endless, bearing in mind of course that the process must be designed with care and that accurate molds are produced.

Try Made by Aria Now

All information and uploads are secure and confidential.

Categories

Share On

Recent Post