The sheet metal bending process is the use of pressure equipment and special die metal sheet metal processing into three – a dimensional processes. Due to the different material, thickness, length, and width of the sheet metal and the different shapes and Angle of the forming, the cargo and size of the pressure equipment bending machine are different. The upper and lower die’s height, shape, and amplitude are different, and the special mold shape is also different.

The bending process can be divided into three categories: local bending closed bending, and embossed bending.

Local bending: Right bending and obtuse bending method selects the upper die below 88 degrees and V= 12T (slot width V, material thickness T) of the lower die.

Closed bend: use the Right Angle and obtuse Angle 90 degrees bending method. Near bending die V=6~ 12T.

Bending: right-angle bending selection of 90 degrees on the die. (Standard right Angle bending). Bending die V=5~ 6T.

Sheet metal processing in the bending process, if you want to increase the bending speed, the gear switch can be operated in a single or continuous state, but for safety, usually only in a single action.

When bending a long part, the middle Angle is usually very large. We can adjust the CC axis to change the Angle in the middle to get the same Angle as the left and right sides. In the process of bending, we should also pay attention to the principle of center bending, which is an important premise to ensure bending accuracy.

The guide to bending sheet metal parts

Bending is the use of pressure to force the material to produce plastic deformation so as to form a certain Angle and curvature shape of a stamping process. Commonly used bending includes V – bending, Z – bending, and bending pressure equality.

1. Bending height:

Bending height is at least two times the sheet metal thickness plus bending radius, bending height is too low, sheet metal bending distortion, it is not easy to get the ideal shape of parts and the ideal dimensional accuracy.

When the bending is the hypotenuse, it is most likely to occur because the bending height is too small to cause the bending distortion. As shown in Figure 4-10, in the original design, the leftmost bending height is too small, it is easy to distort during bending, resulting in low bending quality. In the improved design, the left bend height can be increased, or the smaller part of the bending height can be removed.

2. Bending radius:

To ensure the bending strength, the bending radius of sheet metal should be greater than the minimum bending radius of the material. The following table shows the minimum bending radius Rmin of standard sheet metal materials.

Of course, the sheet metal bending radius is not larger. The better. The bending radius is larger, the greater the bending rebound is, and the harder it is to control the bending Angle and height. Therefore, the bending radius of sheet metal must be set appropriately.

Sheet metal mold manufacturers tend to bend a radius of 0 so that the radius is not easy to rebound after bending. Bending height and bending Angle size are easier to control. But the bending radius of zero bending is easy to cause sheet metal to bend outside, crack, or even break. At the same time, sheet metal bending strength is relatively low, especially for the harder sheet metal material. After a production period, the Right Angle of the mold will gradually smooth, and bending size will become difficult to control.

In order to reduce the bending force and ensure the bending size, another way used by sheet metal mold manufacturers is to increase the pressing process in advance before the bending process. Of course, such a design will cause sheet metal bending strength relatively low and easy to fracture and other defects.

3. Bending direction

Sheet metal bending should be perpendicular to the direction of metal material fiber as far as possible. When sheet metal is bending parallel to the direction of the metal material fiber, it is easy to crack in sheet metal bending. Bending strength is low and easy to crack.

4. Avoid bending failure caused by bending root can not press material

Sheet metal bending, often because other features distance sheet metal parts too close, resulting in can not press material and can not bend or bend serious deformation, generally speaking, in the sheet metal bending root at least need to ensure that two times the sheet metal thickness and bending radius distance on no other features block sheet metal bending material.

5. Ensure bending clearance and avoid bending interference

Due to sheet metal fabrication tolerance, in the direction of sheet metal bending movement, it is necessary to ensure a certain bending clearance to avoid bending failure caused by interference.

6. Ensure bending strength

Sheet metal bending must ensure the bending strength, long and narrow bending strength is low, and short and wide bending strength is high, so sheet metal bending is as far as possible attached to the longer side.

7. Reduce sheet metal bending process

As can be seen from the figure above, the original plate design required two bending processes. After modification, only one bending process is required.

Try Made by Aria Now

All information and uploads are secure and confidential.

8. Avoid complex bending

Similarly, the more complex the sheet metal bending process, the higher the mold cost, the lower the bending accuracy, and complex mold bending may lead to waste of parts material. Therefore, when the sheet metal parts have a complex structure, it can be considered to split the complex bending parts into multiple parts, contributing to the cost and improving product quality.

9. Holes in multiple bends are difficult to align

Why do the screw holes or pull nails in sheet metal bending always misalign so that the screw or pull nails cannot be fixed? This is because sheet metal bending tolerances are large, especially when multiple bending.

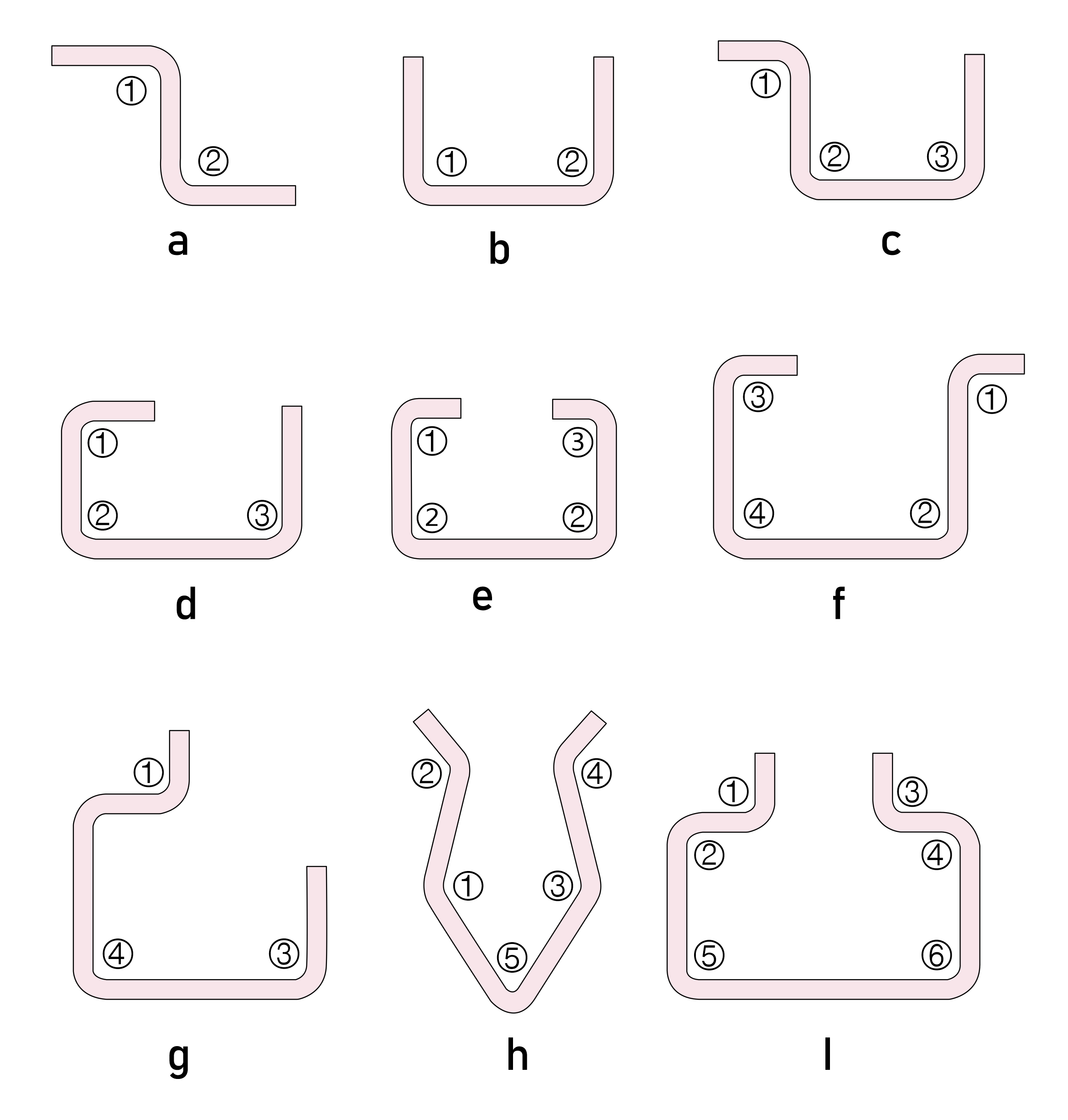

10. Sheet metal bending general order

① The first short side after the long side: generally speaking, the four sides have bent; bending the short side after the long side is conducive to the processing of the workpiece and bending mold assembly.

② The first periphery after the middle: under normal circumstances, generally from the periphery of the workpiece to the center of the workpiece bending.

③ The first part of the whole: if there are some differences from other bending structures inside or outside the workpiece, it is generally the first bending of these structures and then bending other parts.

④ Consider the interference, reasonable arrangement of the bending order: bending order is not invariable according to the shape of the bending or the obstacles on the workpiece to adjust the processing order.

Several common bending sequences

11. When sheet metal parts are bent many times, what should we pay attention to

① To consider whether the bending machine’s cutting tool meets the drawing paper R requirements.

② To see whether the next bending machine knife or fixture blocks the position of the next bending.

③ Look at the last bending in this bending, whether the bending tool and fixture rub, collision.

④ To see whether the final bending tool and bending fixture brush collision.

⑤ If the size of the last bending can be used as the positioning reference for the next bending.

Try Made by Aria Now

All information and uploads are secure and confidential.

Categories

Share On

Recent Post

Everything You Need To Know About Annealing Processes

The chemical composition and internal structure of a material are

Spotface vs Counterbore, What is difference?

As a professional engineer of more than eight years of