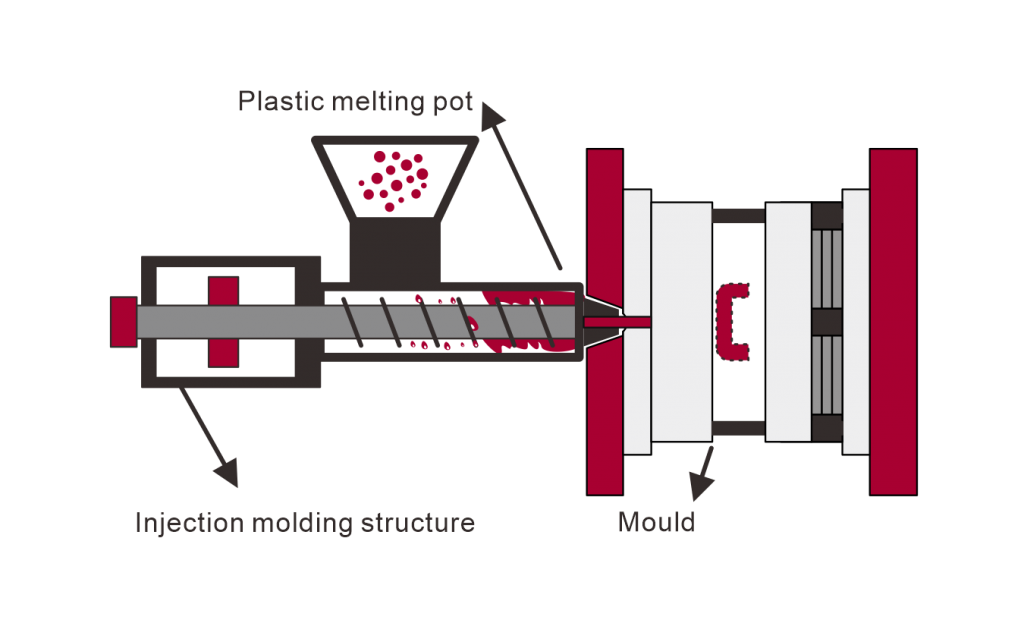

The molten plastic is injected into the mold, the liquid plastic cools and solidifies in the mold, and the cooled plastic product is removed from the mold, which is how injection molding works.

Injection molding is the most commonly used method in plastic molding. The reason is that even complex shapes can be mass-produced as long as molds are made. In injection molding, by changing the mold, a variety of products are produced, from small to large, from simple to complex, reducing the production cycle but also saving costs.

In plastic molding, many products (second only to injection molding) include extrusion molding and blow molding. In the case of extrusion molding, the equipment is usually very large, and due to mixing with various additives, they are usually manufactured by large companies (such as material manufacturers).

The molding method will be explained below.

Injection molding:

The plastic is melted at temperatures around 200°C, pushed into a mold, which cools and solidifies. The injection molding machine consists of two main pieces of equipment. Push syringes and other equipment into the molten plastic and lock the “spray device” and “clamping device” to prevent the mold from opening.

The injection device consists of an injection mechanism such as a syringe and a “plasticizing mechanism” to melt the plastic. The clamping device has a mechanism for opening and closing molds and an ejection mechanism for taking out finished products.

Next, the die is tightened with a clamping device. The part of the syringe outlet that connects to the top of the cylinder (called the nozzle) is then pressed firmly against the hole in the mold inlet. When you press the screw, the accumulated plastic is pushed into the mold, cooled, and solidified. Plastic contracts as it hardens, so add a little melted plastic after all the filling is done.

The pressure during injection molding is 2,000 KGF/cm 2 and 200-500 KGF/cm 2 in the mold. The mold requires about 150 tons of clamping force, so it cannot be easily opened. The large mold weighs 50 tons, and the clamping force of the molding machine is about 3,000 tons. The efficient production of high-precision products characterizes injection molding. But machines and molds are very expensive. Therefore, this method is suitable for mass production.

The metal parts are first put into the mold for mixed metal and plastic products, and the plastic is then injected around the mold. This method is called insert molding.

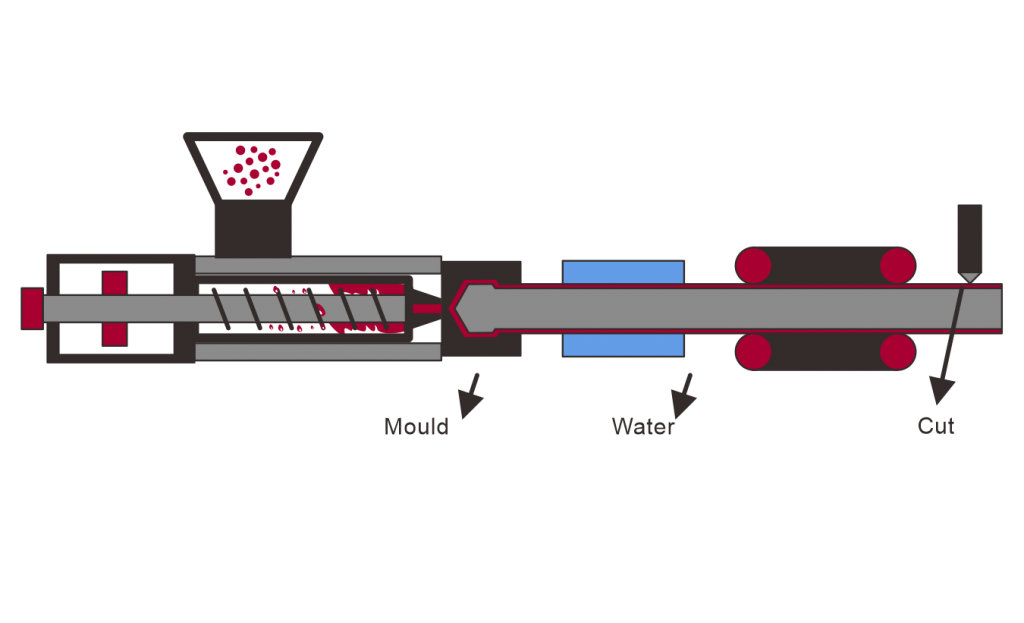

Extrusion molding:

It is called extrusion because the plastic is pushed from the extrusion (die) part and comes out. The typical product is a vinyl chloride pipe. This mold is a type of mold. According to the product’s shape, there are various sectional shapes, such as round and square.

The raw material is mostly plastic powder rather than particles for injection molding. The formed plastic just out of the extrusion mouth has not cooled, easy to deformation, so in order to suppress deformation, after extrusion and then circulation.

The bellows on the washing machine can also be made by extrusion molding. This is then extruded, and compressed air is sent to a Caterpillar for molding. In addition, by designing extrusion holes and punching holes inside and outside the mold, the internal and external molds can rotate and push each other to form a grid.

T die extrusion:

In GB, a slice with a thickness of more than 0.25mm is called a slice, and a slice with a thickness of less than 0.25mm is called a film. The extrusion die head has an elongated shape. It is called t-mode extrusion because it extends in a T-shape in the direction of extrusion.

The process of increasing the wind speed and stretching the sheet in the length direction is called stretching. The plastic is strengthened by stretching it lengthwise, and by performing a process called biaxial stretching, which stretches not only in one direction of the flow but also in the left and right directions, a film can be made strong both in length and perpendicular to it.

Categories

Share On

Recent Post

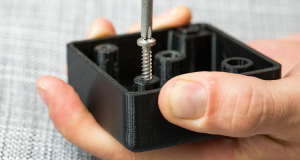

Self-tapping Screws Of Plastic Injection Molding Parts

In the development and design stage of new products, the

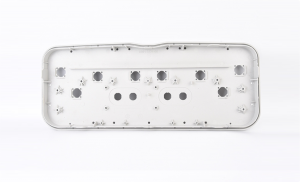

Injection Molding Screw Post Design Guide

The screw is one of the most commonly used locking