Plastic products commonly used in daily life are completed by injection moulding. The injection moulding process is the hot plastic dissolved into the metal mold, after cooling, demould, and other methods—the final form of designer-specific product shape appearance.

Since the 21st century, with the maturing of injection molding technology, the demand for injection molding products from all walks of life has increased sharply, resulting in more and more fierce competition in the injection molding market. Therefore, how to improve the quality of injection moulding products and speed up the production cycle of injection molding products is the whole industry’s complex problem.

What is affects the product quality and production efficiency of injection moulding?

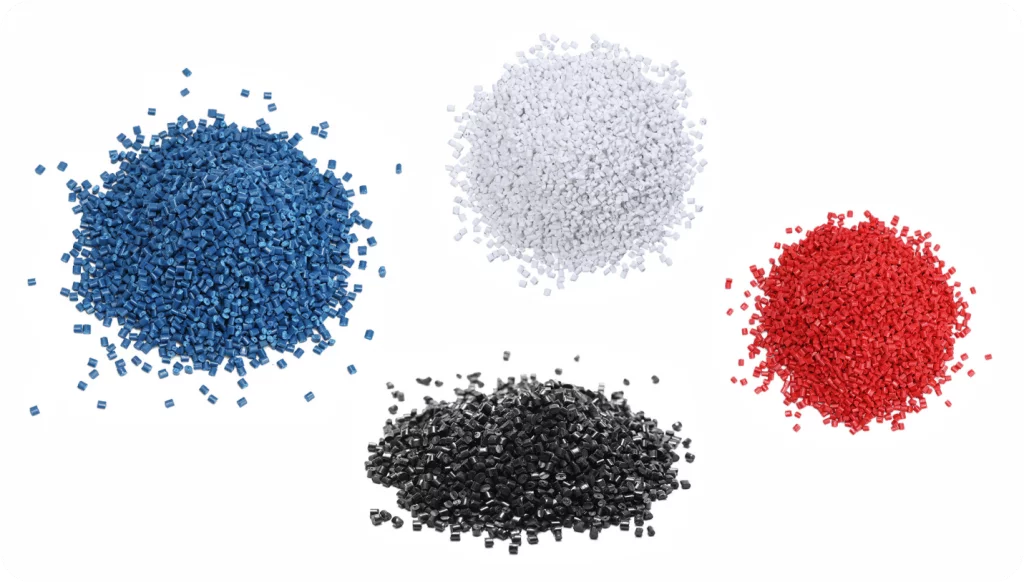

1. Injection Materials

Before purchasing raw materials for injection molding, we need to understand the feature of various materials. Such as melting point, shrinkage, dimensional stability, wear resistance, high-temperature resistance, chemical resistance of the material.

The typical injection materials include Nylon, PEI, POM, PEEK, ABS, PP, PC, LCP…

2. Injection Molding Machine

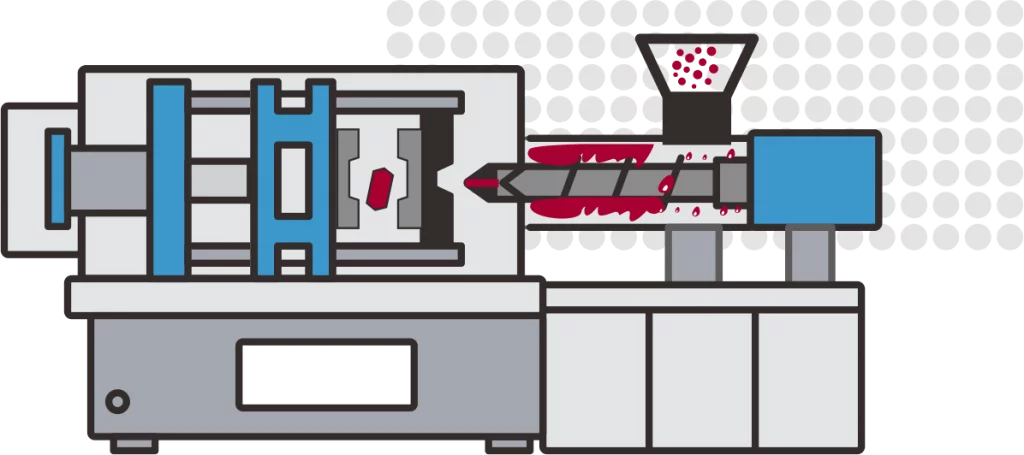

What is the working step of the injection molding machine?

Step 1

Injection molding is to add the product raw material bucket into the injection molding machine hopper, into the material cylinder, and to heat the gasket of the injection molding machine, to melt the raw material added;

Step 2

After the high speed and high pressure, the melted liquid raw material is sprayed into the groove of the mold through the nozzle of the injection molding machine.

Step 3

The molten raw material in the injection mold after maintaining the pressure and cooling effect, so that the raw material in the mold solidified and finalized, in the action of the mold closing mechanism, the mold be opened, molding products through the ejection device from the mold.

This is an injection molding process simply. Check more detail about the injection molding process.

What is the Structure of the injection molding machine?

According to the outer frame, the shape can be divided into three types: vertical injection moulding machine, horizontal injection molding machine, and full electric injection molding machine.

Injection molding machine is a thermoforming machine for the injection molding process and production of plastic injection molding parts. The main parts include hopper, feeding device, build, hydraulic system, heating system, control system, injection mechanism, mould parts.

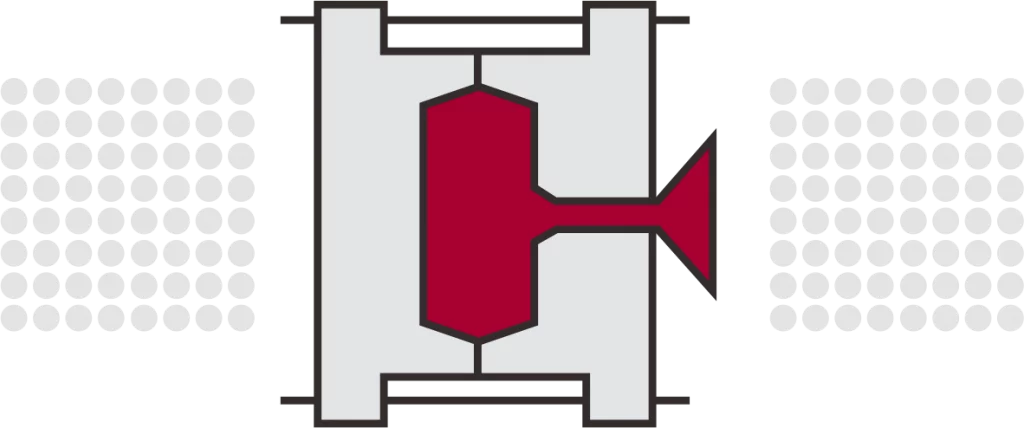

3. Injection Molding Mould

Injection mould is a mold used to produce plastic parts; First, the designer uses 3D software to design the product’s complete structure and exact dimensions. Then, the factory engineer threw CNC engraving, EDM, and other processes into the metal mould. Finally, the factory produces complex parts in large quantities through injection moulds. Injection mould can ensure the quality of each product while effectively improving the production efficiency of injection products.

Categories

Share On

Recent Post