The first CNC milling machines were created in the 1950s as a response to the need for more precise and repeatable machining than what was possible with manual milling machines at that time. These early CNC machining machines were large, expensive, and required highly trained operators.

Over time, CNC machining technology has become more affordable and user-friendly, making it a popular choice for both small shops and large manufacturers. Today, CNC machining services are available in a wide range of sizes, with capabilities that range from simple two-dimensional (D) cutting operation to complex three-dimensional (D) machining.

What is CNC milling?

CNC stands for computer numerical control. CNC milling is a subtractive manufacturing process that can create a wide range of parts from metal, plastic, and other materials.

This guide will provide an overview of what cnc milling is, how it works, the different types of milling, and the many applications for which it is used. We’ll also discuss the machining tolerance of milling, materials that can be milled, surface finish options, and the production cost of cnc milling operations. Finally, we’ll offer some advice on what to consider when choosing a CNC machining manufacturer.

How does cnc milling works?

Milling processes uses computer-controlled rotating milling tools to remove material from a workpiece. The rotational speed and direction of the tools, as well as the linear speed and direction of the workpiece, are all controlled by a computer. This allows for very precise removal of material from the workpiece, resulting in parts that meet tight tolerances.

There are three axes on a typical CNC milling machine: the X-axis, Y-axis, and Z-axis. The X-axis and Y-axis are the horizontal axes, and the Z-axis is the vertical axis. The plain milling cutters is mounted on the spindle, which is located on the Z-axis.

The computerized controls the position of the milling cutter in relation to the workpiece. The machine tools can move along all three axes, but the most common type of milling machine has a limited range of motion along the Z-axis. This is because the tooling must be able to reach all areas of the workpiece, which is not possible if the Z-axis is too small.

Steps of CNC Milling Process:

① A CAD file is created of the desired part.

② The CAM software is used to create a CNC program that will control the tooling and workpiece.

③ The CNC program is loaded into the machine.

④ The workpiece is mounted on the CNC machine and the tooling is installed.

⑤ The CNC machine is started and the tools begins to remove material from the stationary workpiece. (workpiece Milling operation execution)

⑥ The finished part is unloaded from the CNC mill machine.

Cutting Tools selection

The type of material that you are machining will also have a big impact on the type of tools that you need. The three most common types of cutting tools are carbide, high speed steel, and cobalt.

Carbide is the strongest of all the cutting tools and is best suited for machining hard metals.

High speed steel is best suited for machining soft metals.

Cobalt is best suited for machining stainless steel and other difficult-to-machine materials.

CNC Milling Methods

The most common CNC milling methods:

Plain milling:

Also called flat surfaces milling or slab milling, it is the process of machining a flat surface with a rotating end mill. The main advantage of plain milling is that it can be done on any type of machine, including machines.

Angular milling:

This milling operation causes the axis of rotation of the tool to be at an Angle to the workpiece surface, resulting in a design-specified angular cut, such as a groove or dovetail.

Face milling:

It uses an axis of rotation perpendicular to the material surface. The face milling cutters or grinding tool faces down on the workpiece surface to remove the material.

Form milling:

This operation forms shapes by milling away material to create the desired shape.

Drilling:

The process of making a hole with a rotating drill bit. Drilling is the most common type of CNC mill operation.

Reaming:

The process of enlarging a hole with a rotating reamer. Reaming is often done after drilling to achieve a better finish on the surface of the workpiece.

Tapping:

The process of making threads with a rotating tap. Tapping is often done after drilling to create internal threads in a workpiece.

What is cnc milling machines?

There are two main types of CNC milling machines: vertical and horizontal.

Vertical milling machines have a cutting tool that is mounted on a spindle that is positioned vertically. The workpiece is clamped to the table and can be moved in the X- and Y-axes. Vertical CNC milling machine are best suited for smaller parts that require a high degree of precision.

Horizontal milling machines have a cutting tool that is mounted on a spindle that is positioned horizontally. The workpiece is clamped to the table and can be moved in the X- and Y-axes. Horizontal machines are best suited for larger parts that do not require a high degree of precision.

The type of CNC milling machine that you choose will depend on the size and complexity of the parts that you need to produce. If you are unsure which type of machine is best for your application, be sure to consult with a qualified CNC milling manufacturer.

What is 3 axis, 4 axis and 5 axis CNC milling machine?

The number of axes on a CNC milling machine determines the degree of freedom it has to move the cutting tool around the workpiece.

A 3 axis machine has three linear axes: X, Y, and Z. This is the most common type of CNC milling machine and is best suited for smaller parts that do not require a high degree of precision.

A 4 axis machine has four degrees of freedom: X, Y, Z, and A (rotation around the X-axis). This type of machine is best suited for parts that require a high degree of precision, such as turbine blades. This type of machining is used in a variety of applications, including aerospace engineering, automotive manufacturing, and medical device production.

A 5 axis machine has five degrees of freedom: X, Y, Z, A, and B (rotation around the Y-axis). It’s a process that involves using five axes to create or modify a product. This makes it possible to produce more complex shapes and designs than with traditional 3 axis machining.

Materials

Aluminum is a soft metal that is easy to machine. It is often used in the automotive industry because it is lightweight and has a high strength-to-weight ratio.

Brass is a strong metal that is resistant to wear and tear. It is often used in the aerospace industry because of its high resistance to fatigue.

Steel is the strongest of all the metals that are machined with CNC machines. It is often used in the construction industry because of its high strength and durability.

In addition to the three commonly used materials, metal materials of CNC milling aslo including copper, titanium and magnesium .

Of course, The plastics also can be used in CNC machining.

For example:

ABS,

PMMA,

HDPE,

Nylon,

PC,

PP.

In general, any material that can be machined using traditional methods such as drilling, turning, and milling can also be machined using CNC milling.

Application industry

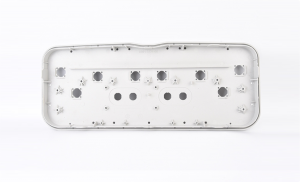

CNC milling services can be used to create parts with a variety of shapes and features, including slots, pockets, and threads. CNC milling services are also capable of drilling and tapping holes.

Some of the most common applications include:

- Creating prototypes, Custom manufacturing services according desired shape;

- Producing small batches of parts;

- Creating complex shapes and designs;

- Machining difficult-to-reach areas.

Milling services are used in a variety of industries, including:

Aerospace engineering

The aerospace industry is one of the most demanding industries when it comes to the precision of parts. CNC servics are used to create a variety of machine parts for aircraft, including turbine blades and fuselage panels.

Automotive manufacturing

The automotive industry also relies on CNC process to produce a variety of parts, such as engine blocks, electric motor and transmission housings.

Medical industry

CNC mills are also used in the production of medical devices, such as hip implants and artificial heart valves.

Jewelry making

In the jewelry industry, CNC mills are used to create a variety of custom designs.

Prototyping

By CNC milling services, Prototypes can be created quickly and accurately, which helps to save time and money in the long run.

Tool and die making

Tools and dies are used cnc processing servcies to create a variety of parts, such as engine blocks and transmission housings.

Benefits of cnc milling:

There are several benefits of using CNC process services.

First, CNC milling machines are very precise. They can produce parts with extremely tight tolerances.

Second, CNC milling is a very versatile process. It can be used to create parts with a wide range of shapes and features.

Third, CNC milling is a fast and efficient process. It can produce large numbers of parts in a short amount of time.

CNC milling VS CNC turining

The difference between CNC turning and milling is which part actually moves — the machine itself or the raw material. CNC milling involves the material being held in place while the tool rotates around it. CNC turning, on the other hand, requires the tool to remain in the same position while the material rotates at a rate to create the exact shape.

How Does it Help You Get Great Parts?

CNC milling is a great way to get high quality parts. There are many factors that you need to consider when you are choosing a CNC machining machine, such as:

The type of machine that you use.

The type of material that you are machining operations.

The accuracy of the CNC machines.

The surface finish of the cnc parts.

The production cost of the milling parts.

The turnaround time of the machine.

All of these factors will help you get great parts by CNC machining. If you take the time to consider all of these factors, you will be able to find a great CNC milling machine that will help you get the parts that you need. Contact Aria (CNC milling machine supplier) today to learn more about what we can do for you.

What should be considered when choosing CNC milling manufacturer?

There are a few things that you should consider when choosing a CNC milling manufacturer:

The size of the company. A larger company will have more resources and experience than a smaller company.

The location of the company. A company that is closer to you will be easier to work with and will likely be more responsive to your needs.

The experience of the company. A company that has been in business for a longer period of time will likely have more experience than a newer company.

The price of the services. You should get quotes from several companies before making a decision.

The quality of the services. Be sure to read reviews and ask for references before choosing a company.

Now that you know what is CNC milling services, and what are the advantages and disadvantages of it. In the next article, we will introduce to you the types of CNC milling machines. Stay tuned!

Try Made by Aria Now

All information and uploads are secure and confidential.

Categories

Share On

Recent Post

Plastic Forming Processes: Methods, Materials, and Applications

Plastic is used in nearly every product we touch. From

Types of Pins: A Complete Guide

Mechanical fasteners are small devices that are usually used to mechanically

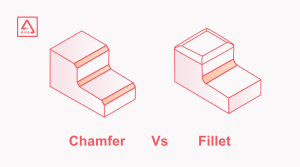

Fillet vs Chamfer: What is the Difference?

In the world of manufacturing, small details can have a

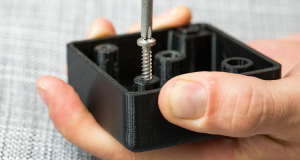

Self-tapping Screws Of Plastic Injection Molding Parts

In the development and design stage of new products, the

Injection Molding Screw Post Design Guide

The screw is one of the most commonly used locking

Plastic Forming Processes: Methods, Materials, and Applications

Plastic is used in nearly every product we touch. From

Types of Pins: A Complete Guide

Mechanical fasteners are small devices that are usually used to mechanically