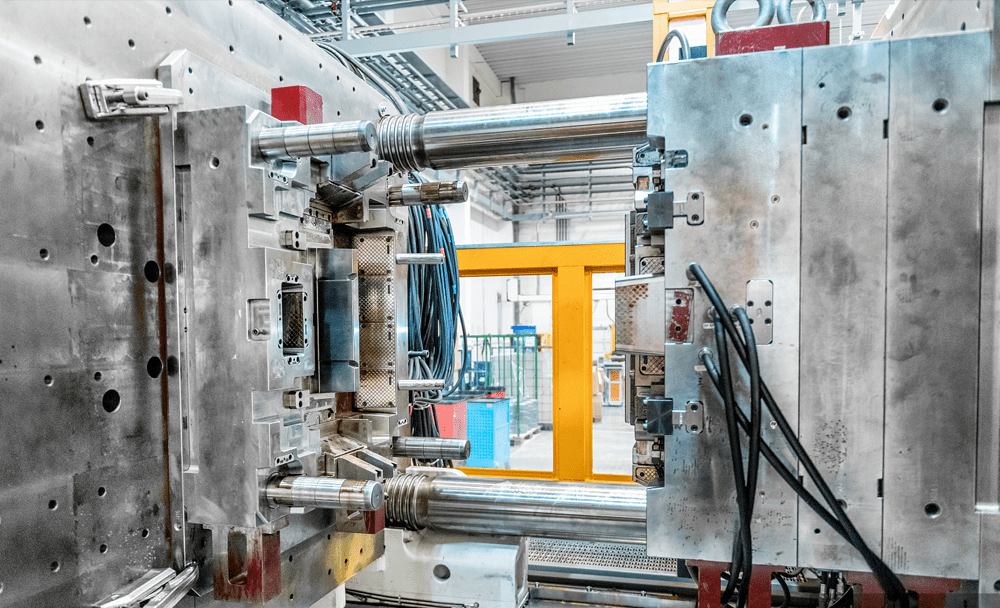

Start with the fact that injection molded prototypes is an experimental process that can be carried out by design teams in tangible forms (in various materials), as well as in digital forms – it all depends on the field in which we operate and the set goal.

In short: a prototype molding is simply the first control item (or one of the first items) of a new product or a product that is significantly changed compared to products previously produced. It is performed in order to evaluate the introduced design changes.

The prototype molding tests are to assess the suitability of the product, its technical and operational characteristics, as well as to verify the construction documentation (e.g. compliance of the actual parameters with the assumed ones), and sometimes also technological (if it exists).

Economy of Scale: Economy of Scale In most cases, prototype mold is the most cost-effective option for an order of 100–2,000 units : too many for 3D printing, CNC machining services, or urethane casting, but not enough to justify mass production tooling.

Definition

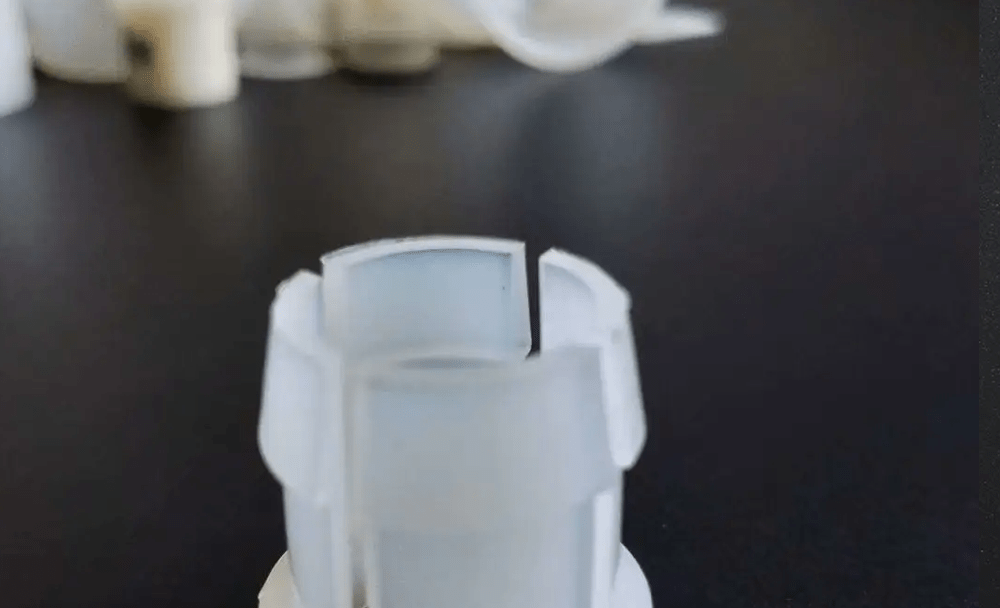

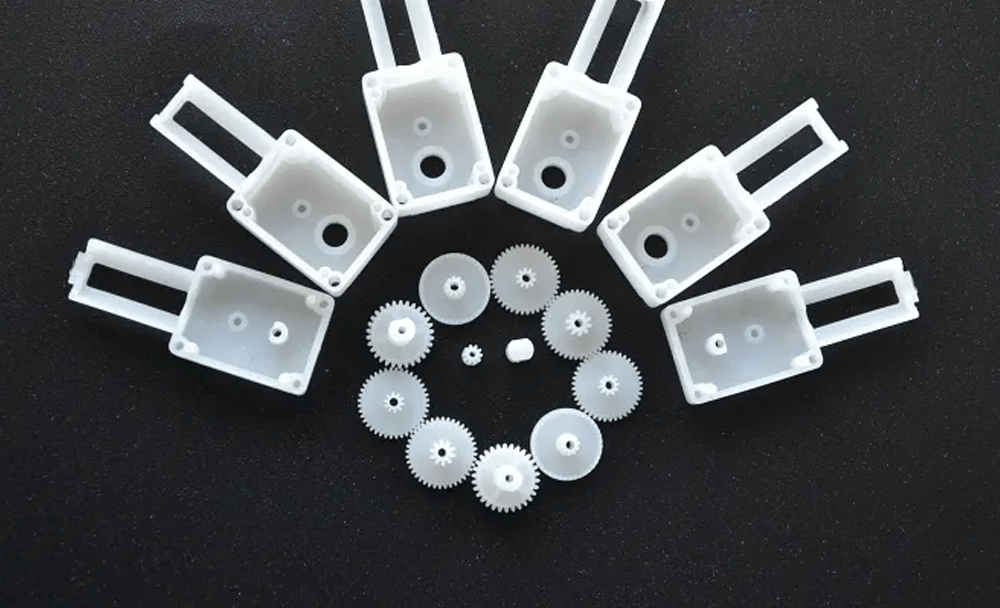

Prototype injection molding is a fast production technique for plastic parts. It is also the development process for new injection molding parts.

It can be used for rapid manufacturing of plastic molded parts, reduce the mold cycle is short, simple process, easy to popularize, mold cost is low, precision and life can meet the needs of a particular function, comprehensive economic benefit is good, especially suitable for new product development trial production, process verification and functional verification as well as many varieties of small batch production. It can obtain more orders for plastic injection molding company.

The advantages of prototype injection molding

Prototype injection molding process can be made to compare the features of the product with the already existing product (s) – it is often able to warn theproduction plant against losses related to the introduction of a defective, obsolete product into circulation, with features that do not suit potential buyers.

For this reason, rational preparation and reliable testing of the plastic injection molded parts are of great importance in mass and high volume production. It must be at the prototyping stage that all possible defects or elements that require refinement are identified because the costs of a poorly performed operation can be significant and severe.

We test prototype production on a specific group of users to have a chance to validate and improve the designs at the right time, and then release to the market a version that meets the needs of the manufacturer and buyers.

Properly used, the role of a prototype, simulating a real and future product, can attract customers to invest in the product, even before allocating the resources necessary for its implementation.

Testing the correctness of the design and early detection of possible design errors before starting production is often not only measurable financial benefits resulting from avoiding unnecessary costs, but also working on the good name of the company and a favorable brand image in the eyes of recipients. It also can be save production costs for low volume injection molding project.

What other values does the use of prototype injection molding bring?

Well, there are many more than just the above-mentioned. Prototypes – used in nearly every industry – help develop aspects of the actual end product and provide the contractor with lots of useful feedback.

At present, rapid prototyping technology has been widely used in injection molding industry, CNC machining services and 3D printing services.

First of all, they show that the execution of the project is feasible, indicate the product features, allow you to test them in practice, and show the final effect of the work, the final aesthetics, and product usability.

They provide factual information on mass production techniques, materials used and costs incurred. Finally – they allow for a real “contact” with distributors, retailers, and customers and test their reaction to the introduced product.

All this will allow for possible changes in the existing plans, which so far were only assumptions and concepts, and now they are based on the actually conducted research. After all, when you do something, it’s best to do it right, after all, everyone cares about success, not failure.

Often – in order to reduce the probability of a complete disqualification of the prototype or the need for its significant modifications (especially when we are dealing with large, heavy machines or devices in small-lot or unit production) – model tests of products are used.

The test result may be used to introduce changes to the model structure (in place of much more expensive product changes) and may allow the elimination of some prototype trials.

In addition to the concept of a prototype, you can also find terms such as prototype series or trial series.

The point of the prototype series is that increasing the number of prototypes means simultaneously increasing the scope of tests or shortening their duration. In turn, the trial series is to check whether the production tooling will guarantee the quality and characteristics of the products the same as in the case of the prototype.

By the way, it is worth mentioning the subject of approval, i.e. prototype tests, the operation and characteristics of which must comply with the existing regulations (e.g. on aircraft engines), and therefore they must be carried out in the presence of representatives of the authorities established to control compliance with these regulations.

A prototype is an innovative process

Just as the road from an idea to a finished product is sometimes long, the creation of the prototype itself (i.e. the first realization of our idea) is related to a whole sequence of structured activities called the innovative process.

What is the process of developing rapid injection molding product innovations?

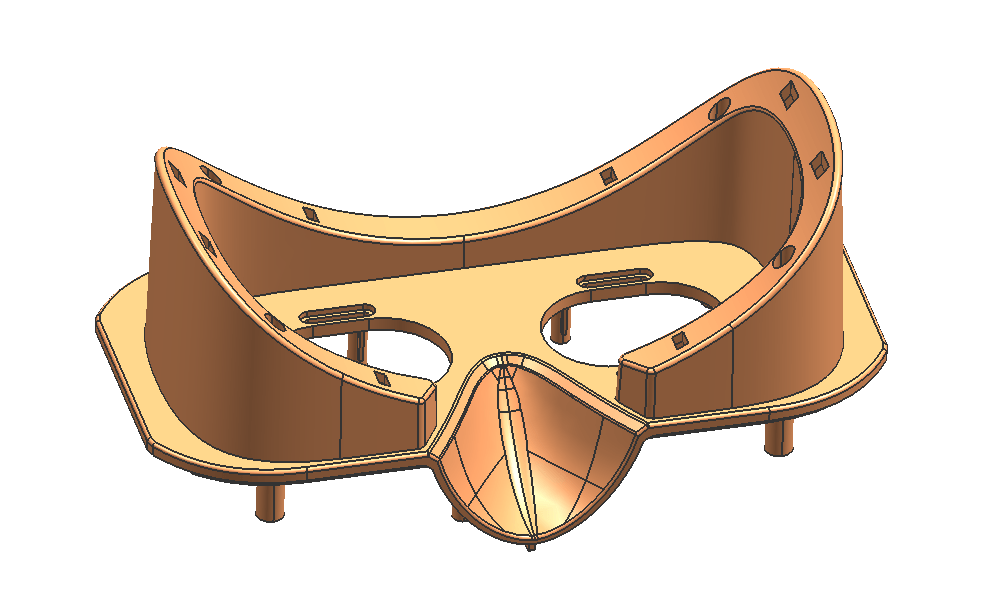

Prototyping technology can quickly transform injection molding project into final injection molded parts. Often multidimensional studies precede the application of a new solution. On the basis of detailed product descriptions (containing data such as components, shape, and size) contained in the technical documentation, test prototypes are constructed.

Their testing – alpha testing – very often takes place with the participation of the client, who indicates which areas require modification and improvement; only obtaining a positive test result redirects the tests to laboratory conditions, where the beta test is started (mainly related to the control of strength parameters and the reaction of the product to extreme conditions).

The results of reliable observations help to introduce possible technical and mass production improvements. Increasingly, attention is paid to the environmental aspect. Protyping manufacturing experience minimize the positive impact of the production cycle and the materials used on the environment.

What is the supply and demand model?

The approach outlined above is, of course, one of many that can be used. There is also a supply model and a demand model. In the first one, we are dealing with an extremely extensive scientific and research structure, providing enormous technical and technological possibilities, and at the same time carrying a number of unprecedented solutions.

In this model, customer feedback is not taken into account, with full consequences, taking the risk of negatively assessing the buyers’ market. The reverse is the demand model, which treats the innovation process as aimed at satisfying customer expectations.

In this case, there is a lower risk of rejection of the product by the clients, but you have to take into account that the product will probably have fewer features described as innovative.

Summarizing the chapter, it can be said that prototype m has its distinct place in the innovation process. It bridges the gap between conceptual ideas and real, workable solutions. It allows developers of various solutions to answer questions and validate/invalidate assumptions, which leads to testing, learning, and improvement of components and complete solutions.

It is a kind of bridge between concepts and the best possible solution. The prototyping process ranges from “fast” or “component” prototyping to “full solution” prototyping and is cyclical in nature.

The typology of prototypes

There are several categories of prototypes and they provide different feedback at different stages of production. Each of these categories has a different function and appearance. Prototype tooling can be made of various materials, on a different scale, and sometimes with a different appearance than the intended end product – and the benefits of each of them will also be different and diverse.

Proof of Concept (PoC) is a demonstration aimed at checking whether a given concept or theory translates into practical potential. In short: this is product design functional testing without full functionality. This model is to check whether materials and products behave as they should.

The decisive advantage of using this prototype category is the ability to make design changes before starting the actual production process. This saves you both money and lead times.

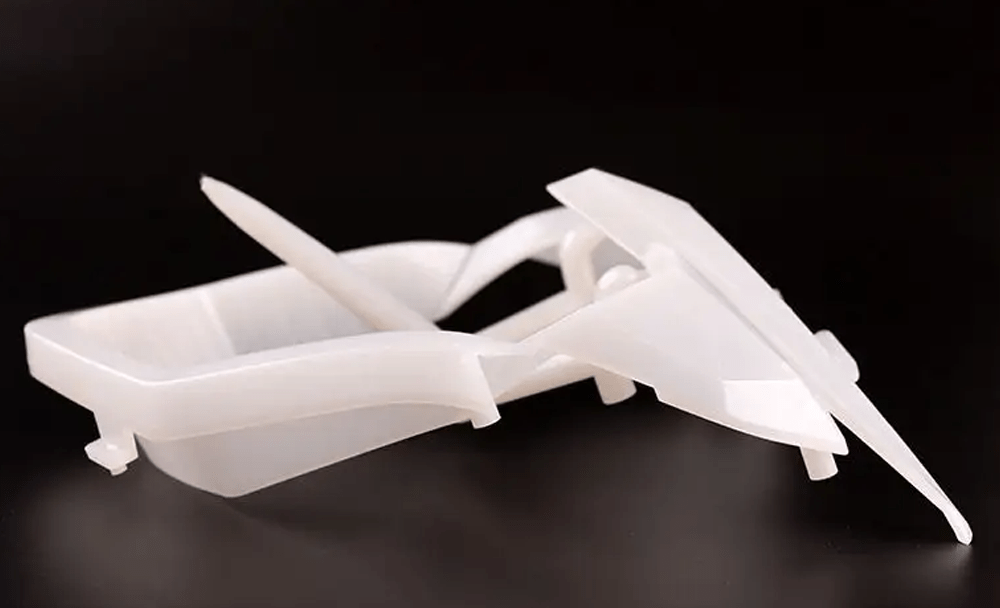

The Visual Prototype

The Visual prototype (visual prototype) is intended to be literally what its name implies, so it is intended to depict the size and appearance of the finished product, rather than focusing on its functionality. It is often used in advertising and packaging marketing.

Part of this category is the Form Study prototype injection molding , emphasizing the geometric features of the design but not pointing to aspects such as color or texture.

The working injection molded prototypes focus on the functionality of the finished product, whether it will perform its functions properly (in order to be able to change the design, if necessary, improve its functionality), and not on its final appearance.

A functional prototype is characterized by the fact that it has both the appearance and functionality of the final product, but it can be made of other materials, on a different scale and using techniques other than the final product. Functional prototypes are often used to obtain funds for production, and when using a different scale or other materials – it is done in order to save.

The User Experience prototype is designed to enable consumer research to indicate whether the product meets the needs and expectations of the end-user. It allows you to check and assess how buyers will use the product, and how they will “interact” with it – and thanks to this knowledge, various improvements can be made that can increase consumer satisfaction.

Benefits of prototype injection molding

So while prototype injection molds is an added cost, it pays for itself many times in the form of a refined product and – which cannot be overestimated – a better brand image.

And thanks to the variety and wide range of prototypes available, no matter if you need to identify production problems, improve some design elements or their functionality, estimate costs and budget, conduct the necessary research or apply for production subsidies – everyone can choose the method according to their needs. needs.

Does prototype injection molding have disadvantages or limitations?

Of course, every stick has two ends.

- One of the major disadvantages is the cost of plastic prototypes. Fortunately, current technologies offer a variety of possibilities – for example, the use of 3D printers to create prototypes allows you to significantly minimize costs.

- You do not have to buy a 3D printer for this purpose, there are companies that do such work on a contract. The Production and Service Portal of LaserTrade brings together a number of such companies through a partner network.

- In the case of very complex processes, it happens that all attention is focused mainly on “how to create a prototype”, and not on the essence, that is, on “what must be done in it”.

- There may be misunderstandings with the customer who does not understand that although he sees the “finished product”, he is in fact only in the early stages of development and not the final solution.

- It may also happen that the attention of the user to whom the prototype will be made available will focus mainly on the behavior and appearance of the proposed solution and not the required usability. Or there may be a temptation to impose solutions on the manufacturer, while the manufacturer himself – having the appropriate knowledge and experience – could develop some better systems.

Conclusion

The benefits of prototyping plastic injection molding are many and they can be used in almost any business environment. It makes plastic injection molding parts possible to quickly provide a visual representation of the final solution. Through rapid prototyping , you can freely formulate your views and ideas.

Precise and detailed rapid prototyping of a selected fragment of functionality can be a useful way to find new technologies or they can be used in the preparation of technical feasibility studies.

Thanks to rapid manufacturing, many companies avoided problems and failure in the form of products that turned out to be non-functional and undesirable on the market, although formally meeting the specifications.

Try Made by Aria Now

All information and uploads are secure and confidential.

Categories

Share On

Recent Post

Laser Welding: What You Need to Know

Traditiona

What Is CNC Milling? A Basic Guide

CNC millin

Types of Metals: A Complete Guide

Before div