Do you have a project that you’re working on that needs to have multiple plastic parts? Or perhaps it’s one that needs to be made out of a durable, high-performance plastic that isn’t easily molded. For whatever your reason may be, you might be considering injection molding, but are unsure about whether or not it’s the right choice for you. Whether you are looking to have plastic parts made to save time, or are simply looking for a high-quality plastic, you should definitely consider injection molding.

1. What is injection molding?

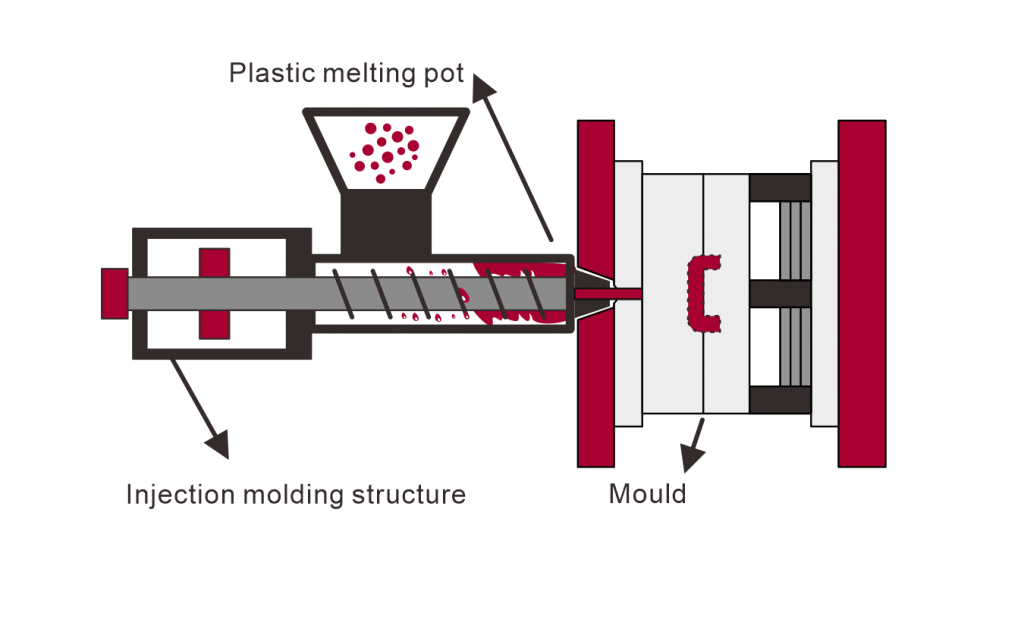

Injection molding is a manufacturing process that uses a controlled force to inject molten plastic into a mold cavity. The molding process allows for a high degree of accuracy and repeatability, making it the ideal choice for high-volume production runs. The injection molding process can be used to produce a wide variety of products, including plastic parts, medical devices and packaging. When it comes to producing high-quality plastic parts, injection molding is the process to choose.

2. Why is injection molding the best option?

When it comes to manufacturing products, there are a few different methods to choose from. Injection molding is often the best option for producing high-quality parts in large quantities.

Here are seven reasons why injection molding is the best option for your next project:

①. Plastic Injection Molding Is Efficient

Plastic injection molding is one of the most efficient ways to produce plastic parts. With injection molding, the plastic is heated until it is in a liquid state. It is then injected into a mold, where it cools and takes on the shape of the mold. This process can be used to create parts in any size or shape. It is also a very fast process, which means that you can get your parts quickly and without having to wait long periods of time.

②. Plastic Injection Molding = Less Investment

Injection molding is a popular manufacturing process that is used to create a wide range of products. The process begins with a heated barrel that melts the plastic. The molten plastic is then injected into a mold, where it takes on the shape of the mold. The mold is then cooled and the plastic part is removed. Injection molding is a popular choice for manufacturing because it is a relatively low-cost process and it produces high-quality parts.

③. Plastic Injection Molding Offers Customization

If you’re looking for a manufacturing process that can offer total customization, plastic injection molding is the way to go. With this process, you can create a mold that perfectly suits the needs of your product. Whether you need a specific size, shape or design, plastic injection molding can deliver. In fact, the possibilities are virtually endless—you can create any type of product you dream up!

④. Plastic Injection Molding Ensures Quality and Uniformity

Injection molding is the perfect process for manufacturing high-quality, uniform parts. The machine applies pressure and heat to plastic pellets, melting them into a liquid form. This liquid is then injected into a mold, where it cools and hardens into the desired shape. Because the injection process is so precise, it’s the ideal method for manufacturing small, intricate parts. And since the molds can be reused over and over again, it’s a cost-effective manufacturing method as well.

⑤. Plastic Injection Molding Offers Savings

It might come as a surprise that plastic injection molding can save you money, but it’s true! In fact, it’s one of the most cost-effective manufacturing processes around. The reason is simple: economies of scale. With plastic injection molding, you only need to produce one tooling die, and you can use it to produce an unlimited number of parts. This is in stark contrast to other manufacturing methods, like machining, which require a new die for every part you produce. So, if you’re looking for a cost-effective way to manufacture your products, look no further than plastic injection molding.

⑥. Plastic Injection Molding Allows Color Control

Injection molding is a manufacturing process for producing parts from thermoplastic materials. Injection molding is used to create a wide variety of parts, from small individual parts to large components. The process begins by heating the plastic until it is in a liquid form. It is then injected into a mold, where it cools and hardens. The mold can be either metallic or made from a molded plastic. The cooled part is then ejected from the mold. Plastic injection molding is a common manufacturing process because it is efficient and produces high-quality parts.

⑦. Plastic Injection Molding Helps Reduced Waste

Plastic injection molding is a process that is used to create a variety of objects, both large and small. This process can be used to create products for both the business and consumer market. Plastic injection molding is a process that is beneficial to both the environment and the economy.

3. Why is injection molding the most affordable option?

When it comes to injection molding, there are a few factors to consider. Cost is always a big factor, and in general injection molding is the most affordable option. That’s because it allows for large production runs, which keeps the cost per unit low. In addition, the molds themselves are relatively inexpensive to make, which keeps the overall cost of the project low. And because the process is so efficient, you’ll save time and money on labor costs.

4. Why is injection molding the most efficient option?

When it comes to manufacturing plastic products, injection molding is by far the most efficient option. With this process, molten plastic is injected into a mold, where it takes on the shape of the cavity. Once the plastic has cooled and hardened, the injection molding mold can be opened and the product removed. This process is quick and economical, and it produces high-quality products that are both strong and durable. Injection molding is the best choice for producing a large quantity of products, and it can be used to make products in a wide variety of shapes and sizes.

5. What to look for when hiring an injection molding company

Injection molding is a process that uses heat and pressure to injection molding machines to shape products from plastic pellets. The products are then ejected from the machine and cooled until they reach their final shape. Injection molding is a common manufacturing process for a variety of products, from medical devices to automotive parts. If you’re looking to produce a product using injection molding, there are a few things you need to keep in mind.

Final Thoughts

Injection molding is the best option for most companies, and when it comes to injection molding, we know what we’re doing. We’ve been helping clients solve their problems and we’d love the opportunity to do that for you! Looking for an injection molder in your area? Contact us today and let’s talk about how we can help with your next project.

Categories

Share On

Recent Post